ʻAno

Mea waiwai

Dina 1.4404 / AISI 316L, Din 1.4539 / Aisi 909

ʻO Mnel, IncNelel, ke kupuʻana, huakaʻi havenlos

Loaʻa nā lako'ē aʻe ma ke noi.

ʻO kāna mea leʻaleʻa: 1 -200 micles

Nā kiko'ī

| Spemification | ||||

| ʻO ka weheweheʻana | kānana maikaʻi | ʻAno | Kohano | Potiwale |

| }m | mm | % | ||

| SSM-P-1.5T | 2-100 | 60 +'Olani Hoʻokū Hokele + 60 + 30 + Pand4x5px1.0t | 15 | 57 |

| SSM-P-2.0T | 2-100 | 30 + hoʻololi i ka mīkini kai + 30 + φ5x7px1.5t | 2 | 50 |

| SSM-P-2.5T | 20-100 | 60 +'Olani Hoʻokū Hila + 60 + 30 + φ4x5px1.5t | 2.5 | 35 |

| SSM-P-3.0T | 2-200 | 60 +'Olani Hoʻokū Hila + 60 + 20 + φ6x8px2.014 | 3 | 35 |

| SSM-P-4.0T | 2-200 | 30 + nā kānana e waiho + 30 + 20 + φ8x10px2.5t | 4 | 50 |

| SSM-P-5.0T | 2-200 | 30 + 'sluter e waiho + 30 + 20 + 10 + 10 + φ + φ8x10px3.0t | 5 | 55 |

| SSM-P-6.0T | 2-250 | 30 + mau mea hoʻohui i ka lau + 30 + 20 + 10 + 10 + 10 + φ8x10pX4.0T | 6 | 50 |

| SSM-P-7.0T | 2-250 | 30 + 'sluter e waiho + 30 + 20 + 10 + 10 + φ + φ8x10px5.0t | 7 | 50 |

| SSM-P-8.0TT | 2-250 | 30 + 'sluter e waiho + 30 + 20 + 10 + 10 + φ + 88x10px6.0t | 8 | 50 |

| ʻO ka mānoanoa o ka papa pulupulu a me keʻano o ka uila e hiki ke hanaʻia e like me nā koi o nā mea hoʻohana. | ||||

ʻO nā'ōlelo hoʻohiki, inā he mea hoʻohanaʻia ma nā multifuncalicalical i ka holoi holoiʻana, hiki i keʻano o ka papa hana heʻelima mau pahu

ʻO ia ka 100 + kānana e kau ana + 100 + 124/64 + 64/124 / 12,0t

ʻO ka mānoanoa o ka papa punching i hoʻopaʻaʻia ma luna o kāu koi ikaika.

Kūponoʻia kēia huahana no nā kikowaena kiʻekiʻe a iʻole ke koiʻana i ke koiʻana i ke koiʻana i ka hana o ka hana maʻamau a me keʻano o kaʻoihana

Noi

Nā meaʻai a me nā holoholona, ka mālama wai,ʻo Dusting, Pharmacy, Gelmay, PolyomS, PoyomS, Poyoms, etc.

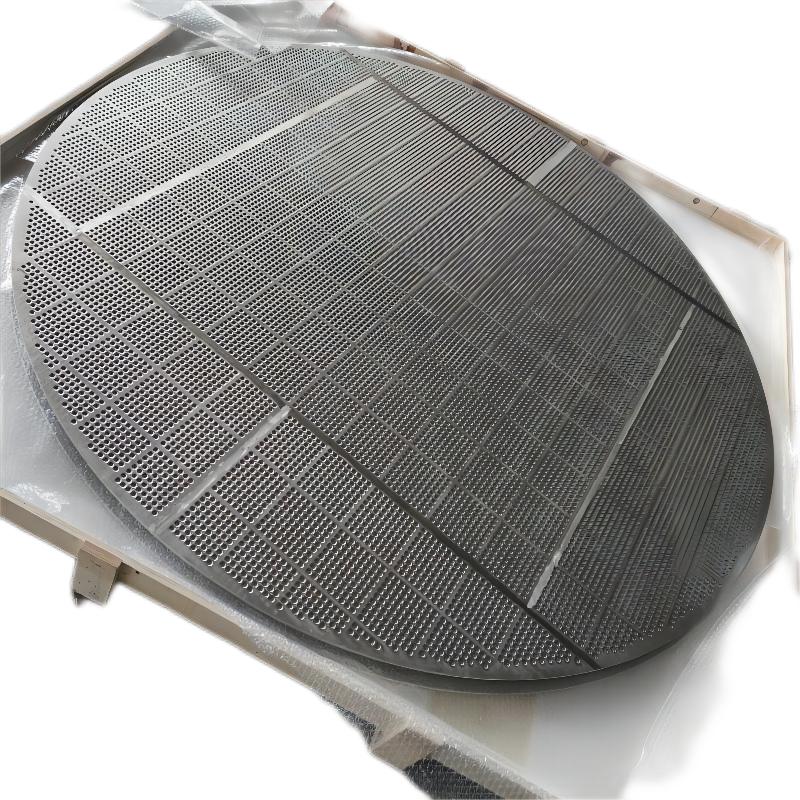

ʻO ka papa hana i hōʻehaʻiaʻo Mesh i keʻano heʻano koʻikoʻiʻo ia e lawehala i ka pā piʻo a me ka base flat i hui pūʻia. Hiki ke kohoʻia i ka papa pulching e like me nā mānoanoa likeʻole e like me nā pono, aʻo ka ulia ulana e hiki ai i hoʻokahi a keu paha. Ma muli o ka papa punching e like me ke kākoʻo,ʻo keʻano o ka hoʻohuiʻana o ka hoʻohuiʻana i ka ikaika nui a me ka ikaika o ka mīkini. ʻO ka mea hana hewa o nā meaʻeluaʻaʻole wale nō ka hopena o ka ea o ka lewa maikaʻi o ka wroven, akā, eia hoʻi ka ikaika o ka penikala o ka pā nui. Hiki ke hoʻokōʻia i loko o ke cylindrical, disc, sheet a me nā mea hana o nā mea kanu, ka meaʻai, metc.

Hoʻolahaʻo PLATE PLATE i nā hiʻohiʻona paʻakikī:

(1) ikaika maikaʻi a me ka ikaika kiʻekiʻe. Ma muli o ke kākoʻo PUCHIKI PLANG PĀNUI, loaʻa iā ia ka ikaika kiʻekiʻe kiʻekiʻe a me ka ikaika ikaika ma waena o nā meshes i hōʻehaʻia;

(2)ʻO ka poho nui kiʻekiʻe, ka poho nui, ka laulā o ka pluratila pololei he 1μ-100μ, a he koi kūpono ia i ka hana playlication;

(3) maʻalahi i hoʻomaʻemaʻe, ua hoʻonaniʻia ka kānana ma kaʻaoʻao, he kūpono no ke kua no ke kua;

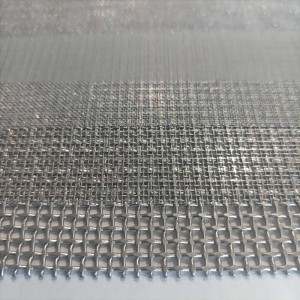

(4)ʻAʻole kūponoʻia, ua hoʻopaʻaʻia keʻano o ka Mess, he lole no ka gap,ʻaʻohe lole makapō.

(5) Ke kū'ē neiʻo Corrosiotion,ʻo ke kū'ē kiʻekiʻe, hiki ke noho ma ke kiʻekiʻe kiʻekiʻe o 480 ℃.

Loaʻaʻo Plate Plate i ka hoʻohanaʻana i ka mesh hoʻohana:

(1) Nā mea hoʻohana i hoʻohanaʻia no ka weheʻana i nā wahi kiʻekiʻe i loko o nā wahi kiʻekiʻe kiʻekiʻe.

)

(3) Orifice Plate waiwai no ka wahi e hoʻoneʻe ai i ka wahi e hoʻoneʻe ai.

(4) Hoʻohanaʻia ia ma Blast Furnace Burnace i ka neʻeʻana o ka bootal pulverized belle a me keʻano hana hoʻopiʻi bhase.

(5) Filtertration, holoi a holoi i nā mea i loko o kaʻoihana lāʻau lapaʻau.

(6) Kākoʻo Catalyst Grille.

(7) Hoʻomaopopoʻia no ka pōkolepane o Plyester, iʻa, meaʻai a me nā mea lawe manu, a me nā hōʻemi wai.