ʻAno

Mea waiwai

Dina 1.4404 / AISI 316L, Din 1.4539 / Aisi 909

ʻO Mnel, IncNelel, ke kupuʻana, huakaʻi havenlos

Loaʻa nā lako'ē aʻe ma ke noi.

ʻO kāna meana kānana: 1 -100 micsons

Nā kiko'ī

| Elima mau kihiʻehā-ʻo Roisedardʻelima | ||||||||

| ʻO ka weheweheʻana | kānana maikaʻi | ʻAno | Kohano | Potiwale | ʻO keʻano maʻi | Rp | Ke kaumaha | Kalima bubble |

| }m | mm | % | (L / min / cm²) | N / cm | kg / ㎡ | (mmh₂o) | ||

| SSM-F-1 | 1 | 100 + 400x2800 + 100 + 12/64 + 64/124 | 1.7 | 37 | 1.82 | 1080 | 8.4 | 360-600 |

| SSM-F-2 | 2 | 100 + 325x2300 + 100 + 12/64 + 64/124 | 1.7 | 37 | 2.36 | 1080 | 8.4 | 300-590 |

| SSM-F-5 | 5 | ʻO 100 + 200x1400 + 100 + 124 + 64/124 | 1.7 | 37 | 2.42 | 1080 | 8.4 | 260-550 |

| SSM-F-10 | 10 | 100 + 165x1400 + 100 + 124 + 64/124 | 1.7 | 37 | 3.08 | 1080 | 8.4 | 220-500 |

| SSM-F-15 | 15 | 100 + 165x120000 + 100 + 124 + 64/124 | 1.7 | 37 | 3.41 | 1080 | 8.4 | 200-480 |

| SSM-F-20 | 20 | 100 + 165x800 + 100 + 124 + 64/124 | 1.7 | 37 | 4.05 | 1080 | 8.4 | 170-450 |

| SSM-F-25 | 25 | 100 + 165x600 + 100 + 124 + 64/124 | 1.7 | 37 | 6.12 | 1080 | 8.4 | 150-410 |

| SSM-F-30 | 30 | 100 + 400 + 100 + 12/64 + 64/124 | 1.7 | 37 | 6.7 | 1080 | 8.4 | 120-390 |

| SSM-F-40 | 40 | 100 + +5 + 100 + 124 + 64/124 | 1.7 | 37 | 6.86 | 1080 | 8.4 | 100-350 |

| SSM-F-50 | 50 | 100 + 250 + 100 + 124 + 64/124 | 1.7 | 37 | 8.41 | 1080 | 8.4 | 90-300 |

| SSM-F-75 | 75 | 100 + 200 + 100 + 124 + 64/124 | 1.7 | 37 | 8.7 | 1080 | 8.4 | 80-250 |

| SSM-F-100 | 100 | 100 + 150 + 100 + 154 + 64/ 124/ 12 | 1.7 | 37 | 9.1 | 1080 | 8.4 | 70-190 |

Nui

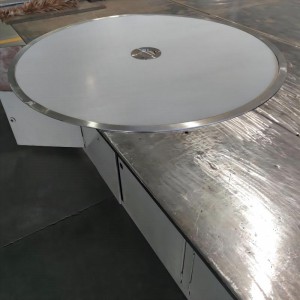

ʻO ka makuahine: 5mm-1500mm

ʻOi aku ma mua o 1500mm, pono mākou e hoʻokaʻawale.

Noi

ʻO nā wahi moe, nā kānana NutsCra, Centrifugges,ʻo ka nohoʻana o Silos,ʻo nā noiʻana i nā noi.

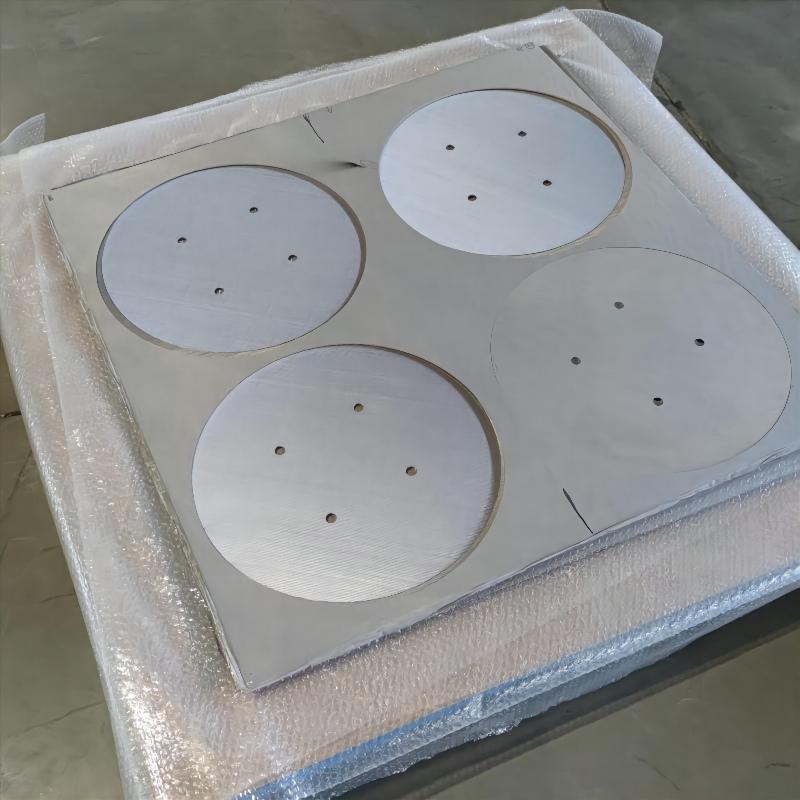

Ua hoʻokaʻawaleʻia ka papa hanaʻelima mau loa i nā'āpanaʻelua iʻehā ʻO keʻano o kēiaʻano kānanaʻaʻole wale wale nō ka lole a me nā kiʻi kiʻi kūpono a he ikaika kiʻekiʻe a me ka ikaika. He mea kiʻi kiʻi kūpono ia no nā hanana e pono ai ke koiʻia. No ka mea,ʻo kona kiʻi kiʻi kiʻi kiʻi kiʻi kiʻiʻia, aʻo ka channel i ka hana hou,ʻoi aku ka maikaʻi o ke kaʻina hana, e hoʻohanaʻia no kekahi hana kānana. He maʻalahi keʻano e hana ai, ke kaʻina a me ka weld, a hiki ke hoʻoiliʻia i nāʻano o nā mea e like me ka pōʻai, cylindrical, cylindrical

thancecture

1

2, hiki ke hoʻololiʻia a me keʻano kūpono loa

3

4.ʻO ka hoʻomaʻamaʻa hoʻomaʻemaʻe maikaʻi loa

Ua hui pū kaʻoihana i nā lako hana holomua, kahi kahua mua-Clast R & CH, kahi'ōnaehana lawelawe kōkua nui, a me kahiʻoihana lawelawe kōkua. E hoʻomau mākou e hoʻomaikaʻi i ko mākou pono pono'ī a me ka pae, a hoʻomau e hālāwai me nā pono likeʻole o nā mea kūʻai aku me nāʻoihana maikaʻi a me keʻano noʻonoʻo.