ʻAno

Mea waiwai

Dina 1.4404 / AISI 316L, Din 1.4539 / Aisi 909

ʻO Mnel, IncNelel, ke kupuʻana, huakaʻi havenlos

Loaʻa nā lako'ē aʻe ma ke noi.

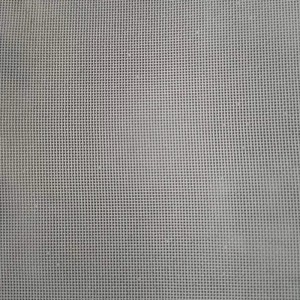

ʻO kāna mea leʻaleʻa: 1 -200 micles

Nā kiko'ī

| Spemification | ||||

| ʻO ka weheweheʻana | kānana maikaʻi | ʻAno | Kohano | Potiwale |

| }m | mm | % | ||

| SSM-P-1.5T | 2-100 | 60 +'Olani Hoʻokū Hokele + 60 + 30 + Pand4x5px1.0t | 15 | 57 |

| SSM-P-2.0T | 2-100 | 30 + hoʻololi i ka mīkini kai + 30 + φ5x7px1.5t | 2 | 50 |

| SSM-P-2.5T | 20-100 | 60 +'Olani Hoʻokū Hila + 60 + 30 + φ4x5px1.5t | 2.5 | 35 |

| SSM-P-3.0T | 2-200 | 60 +'Olani Hoʻokū Hila + 60 + 20 + φ6x8px2.014 | 3 | 35 |

| SSM-P-4.0T | 2-200 | 30 + nā kānana e waiho + 30 + 20 + φ8x10px2.5t | 4 | 50 |

| SSM-P-5.0T | 2-200 | 30 + 'sluter e waiho + 30 + 20 + 10 + 10 + φ + φ8x10px3.0t | 5 | 55 |

| SSM-P-6.0T | 2-250 | 30 + mau mea hoʻohui i ka lau + 30 + 20 + 10 + 10 + 10 + φ8x10pX4.0T | 6 | 50 |

| SSM-P-7.0T | 2-250 | 30 + 'sluter e waiho + 30 + 20 + 10 + 10 + φ + φ8x10px5.0t | 7 | 50 |

| SSM-P-8.0TT | 2-250 | 30 + 'sluter e waiho + 30 + 20 + 10 + 10 + φ + 88x10px6.0t | 8 | 50 |

| ʻO ka mānoanoa o ka papa pulupulu a me keʻano o ka uila e hiki ke hanaʻia e like me nā koi o nā mea hoʻohana. | ||||

ʻO nā'ōlelo hoʻohiki, inā he mea hoʻohanaʻia ma nā multifuncalicalical i ka holoi holoiʻana, hiki i keʻano o ka papa hana heʻelima mau pahu

ʻO ia ka 100 + kānana e kau ana + 100 + 124/64 + 64/124 / 12,0t

ʻO ka mānoanoa o ka papa punching e hoʻopaʻaʻia i kāu noi ikaika

Kūponoʻia kēia huahana no nā kikowaena kiʻekiʻe a iʻole ke koiʻana i ke koiʻana i ke koiʻana i ka hana o ka hana maʻamau a me keʻano o kaʻoihana

Noi

Nā meaʻai a me nā holoholona, ka mālama wai,ʻo Dusting, Pharmacy, Gelmay, PolyomS, PoyomS, Poyoms, etc.

ʻO keʻano heʻelima mau mea i hoʻopaʻaʻiaʻo Mesh Pluster i hanaʻia e nā meaʻelimaʻelima mau mea i ukuʻiaʻo Mesh Ua hanaʻiaʻo ia ka papa inoaʻelima mau papa inoa i hanaʻia eʻelima mau papa o nā papa o nā ceel ceelless cheelless a me ka hoʻomaha. ʻO ka Luna Hoʻomalu i hanaʻia i nā'āpanaʻelima mea haʻahaʻa i loaʻa iā ia keʻano o ka paleʻana,ʻoi aku ka hoʻomaʻemaʻeʻana, a me nāʻoi kiʻekiʻe.

ʻO nā meshes o kēlā me kēia'āpana o ka mea i hoʻopiʻiʻia aiʻo Mesh kānana i hoʻopiʻiʻia e hana i kahiʻano kīwaha, e like me ka ikaika o keʻano, e like me ka ikaika nui, e like me ka ikaika maikaʻi, e like me ka ikaika kiʻekiʻe, a me ka ikaika. Shape Strability Etc. Ma muli o keʻano kūpono a me ka hoʻolālāʻana i ka nui o ka pore ʻOi aku ke kiʻekiʻe o nāʻano kānana i nā mea liʻiliʻi.

1. Nā hiʻohiʻona huahana:

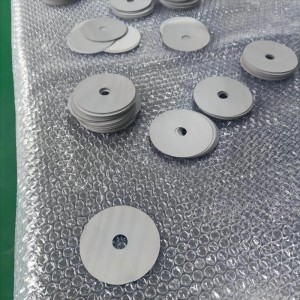

1)ʻO kaʻelimaʻelima mau mea i hanaʻia i kahi papa pale, he'āpana'āpana, a i nā'āpana'āpanaʻelua;

2) ikaika ikaika

3) High Reclion: Hiki iā ia ke hana i ka hana kiʻi kiʻi kiʻi kiʻi kiʻi no ka nui o ka poki

4) Ke paleʻana i ka wela: hiki iā ia ke hoʻohana no ka filtration mau loa mai -200 degere a hiki i ka 650 degere;

5) E hoʻomaʻemaʻe: Ma muli o keʻano kānana i keʻano o keʻano me ka hoʻomaʻemaʻe maikaʻiʻana, e maʻalahi ka hoʻomaʻemaʻe.

6) He kūpono maikaʻi a me ka ikaika kiʻekiʻe,ʻaʻohe pono e hoʻohui i ke kākoʻo kākoʻo,ʻaʻohe mea e hāʻule ana i ka paleʻana,ʻaʻole maʻalahi e hoʻomaʻemaʻe.

2.ʻO ke kumu nui:

1) hoʻohanaʻia e like me kahi mea e wehe ai i nā mea e wehe ai i ka waiwai i loko o ka nohona kiʻekiʻe;

2) Hoʻohana no ka hoʻoiliʻana i ka hau

3) No ka kiʻekiʻe kiʻekiʻe kiʻekiʻe o ke kiʻekiʻe, kiʻekiʻe-reliabli nui kiʻekiʻe;

4) no ka phone ke kalepa o ke kino

5) Hoʻohana no ka flaters o ka polyester, nā huahana aila, nā huahana a me nā mea kanu lāʻau a me nā meaʻala

Nānā: Hiki ke hanaʻia nā dimensiona e like me nā koi o ka mea kūʻai aku. Hiki ke hoʻokōʻia i loko o ka tublar, disc, clarle a me nā mea kānana'ē aʻe.